Technical

So, starting myself

Fairly quickly I found how to wind the

autotransformer for the unun that takes care

of the transformation from a very high Z

in the feeding point of the end-fed 5 band

antenna, and very fast I found the values of

the shortening coils for both the 5 band and

3 band end-fed antenna.

Figure 1

shows the

critical information for constructing the unun,

while

Figure 2

illustrates the element lengths

and coil details.

My first try

For Johan, ON5AH I made the first prototype,

just winding the transformer on a single

FT140-43 core (I had several lying around).

I bought a little ABS box at our local electrics

hardware store and though it was a bit too

large it did the job well enough.

Photo 2

shows the completed unun in its box.

The unun is simply wound and secured with

cable ties. I used solder lugs and little bolts to

make life easier if I had to change anything. As

I only needed to use 80 and 40 metres I left

out the capacitor that would be required for the

higher bands. However, without a capacitor

the transformer only needed 2 + 6 + 6 = 14

windings instead of the 16 windings for the

multiband versions with a capacitor.

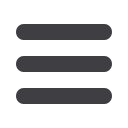

Next, I started building the inductor that

would shorten the antenna to 23 metres total

length. I calculated the necessary inductance

as 110µH using

MMANA-GAL

. I used pieces

of left over copper wire that I found in my junk

box. I stopped at 105µH, checked with my LC

meter, because that was the length of wire I

had handy. I would have had to put in another

solder joint to reach 110µH. 46 turns were

wound on an 80mm PVC tube left over from a

home DIY project.

I stabilised the inductor windings with hot-

melt glue and added solder lugs, nuts and

bolts so I could connect both the antenna

wires to the inductor. The completed prototype

inductor is shown in

Photo 3

.

I used other 2.5mm square (AWG13)

copper braided wires for the antenna wires (of

course I also found these in the junk box). I

hung the antenna from my shack window on

the first floor to a lamp-post across the street.

I started with 21 metres of wire between the

unun and the inductor and with 4 metres of

wire after the 105µH inductor. I had to start

adjusting the long part of the antenna for 40m

first and then adjust the wire after the inductor.

In a little over an hour I had adjusted the right

length for a good SWR on the entire 40 metre

band (SWR <1.5:1) and a SWR across about

100kHz of 80 metres. I went to Belgium the

next weekend so I could give the antenna to

Johan, ON5AH so he could try it and see if it

would suit his needs.

That was the prototype. During testing and

adjusting I compared the antenna with my

other wire antenna and V-dipole and I was

intrigued that such a little stupid antenna didn’t

work badly at all. I also found out that on 80m I

would need more ferrite core because although

the single FT140-43 core could handle 50W it

got warm with 100W of carrier.

So the plan quickly was born to build a

second antenna, to see if I could build an

auto transformer on 2 stacked FT140-43

(still had several of those in the spare-part

department!). Or perhaps even use a single

FT240-43 and if I could get the antenna to

work on the 5 bands it could work, 80, 40,

20, (15) and 10 metres. I already knew that

it was necessary to use a small tuner for 15m

because even the producer of the commercial

product stated this in his website. This second

antenna also would be a very handy holiday or

field day antenna.

Version 2

I starting building the unun and used a similar

case to the first antenna. I used two stacked

FT140-43 cores for the transformer. I used a

68pF 6kV capacitor (a bit on the bulky side,

but I had them in the junk box and you work

with what you have, not with what you would

like

to have). I hot-glued the windings to the

cores and glued the transformer to the bottom

of the cabinet to get good mechanical stability.

After adjusting the antenna length, I found

that it needed more capacitance to lower the

SWR on the higher bands, so I just soldered

an 80pF 10kV in parallel with the 68pF cap. It

didn’t look neat, but the now-150pF did the job.

After placing the second capacitor I

needed to readjust the antenna length again

(it became a bit shorter at the first 20 metre

long section) and SWR was good enough and

about the same as the commercially-produced

antennas.

I had to build a second inductor, for my

antenna, but as I ran out of junk wire I bought

10m of 0.75mm square (AWG 18) twin lead

and tore the wires apart. I wound another coil

on the same grey PVC pipe (the sort normally

attached to guttering at your home to get rid of

the rainwater). This also came out at 105µH.

Fixation was done in a similar way as before

with hot glue, solder lugs and 4mm stainless

steel nuts and bolts, to attach the antenna

wires to the inductor in the antenna itself.

I hung this antenna the same way as I did

with the first and started to get the 21 metre

part before the inductor set for 10, 20 and 40

metres by checking the SWR.

I shortened the wire so the SWR was

perfect on those bands.

Then I started cutting the 4 metre wire

after the inductor for the resonance point on

80 metres. After a bit fiddling I got the antenna

100% right.

I never give precise wire length for the

antennas and I will not give them now, though

in the schedule I found on the internet there

are precise lengths given. I do not work that

way because velocity factor for different wires

and insulation may vary up to 7% so it is

absolutely useless to give precise values, as

I do not know what type of wire or insulation

Jos van den Helm, PA1ZP

pa1zp1@gmail.comPHOTO 3:

Prototype 105µH coil, 45 turns on

80mm PVC pipe (see text).

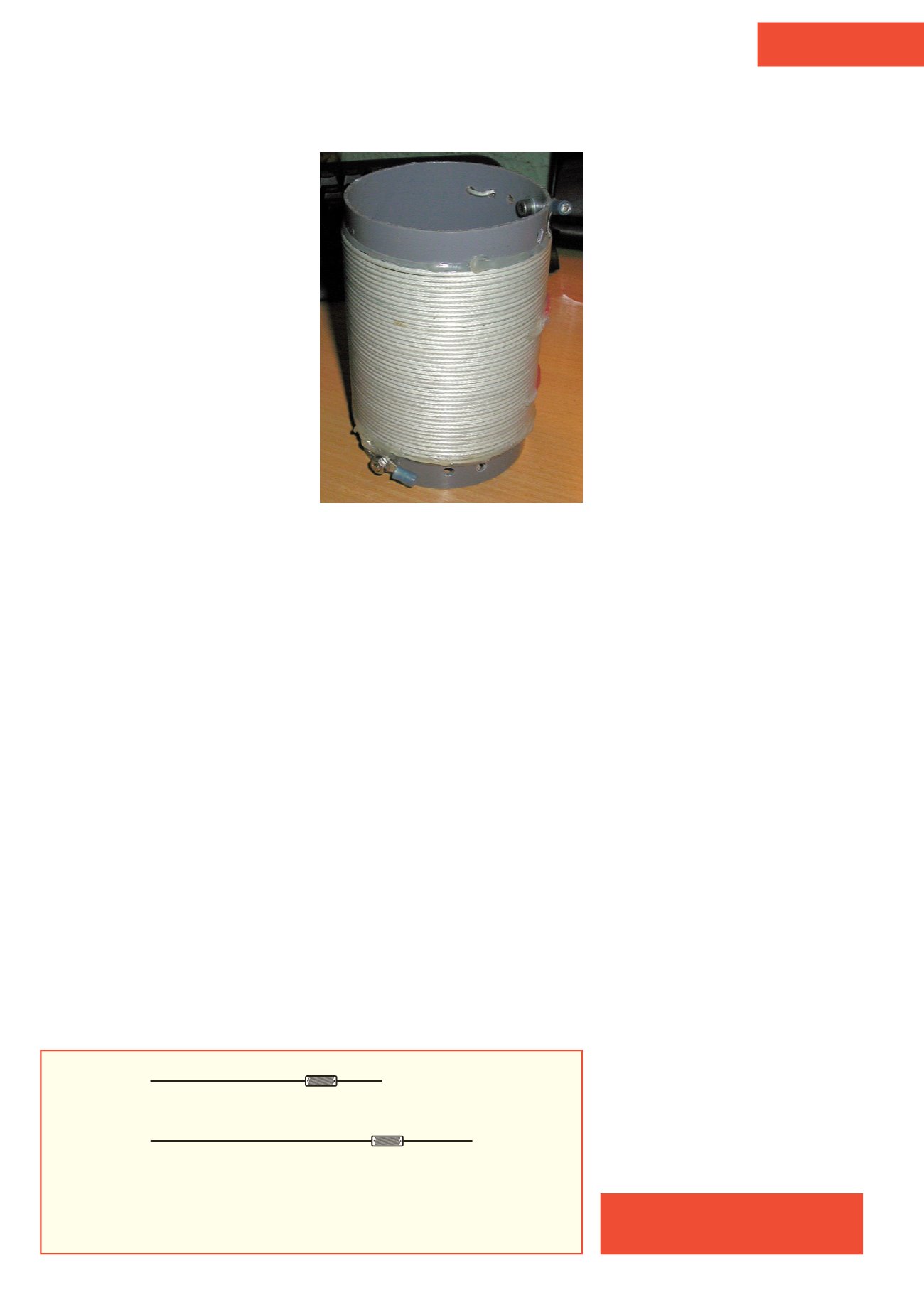

10.1m

34µH 1.85m

40, 20 & 10m version

90 turns

20.35m

110µH 2.39m

260 turns

80, 40, 20, 15 & 10m version

FIGURE 2:

Construction of the two versions of the antenna. The coils are 1mm enamelled copper

wire close wound on 19mm diameter PVC tube. When tuning, start on the highest band and

adjust the length of the longer wire. The end marked C connects to point C of Figure 1. Note that

the wire lengths are for guidance only: the text contains details of how to ‘cut-and-try’.

February 2016

55