February 2016

32

M

any of the circuits used

in radio equipment are

relatively simple. A typical

design will have multiple stages,

each of which can be considered

as a separate block. This

modular approach to design and

construction means that there are

only a few connections required

between each block. In the case of

an amplifier: power supply, input,

output and ground. Such simple

circuits are easily accommodated

on a single-sided PCB layout.

Double sided boards

For more complex circuits, it may be difficult

to find ideal routes for all PCB traces on a

single-sided board without using wire links

or extra components to bridge the gap where

one trace must cross another. In some cases,

PCB designers will include unnecessary

components or dummy devices like the

‘zero-ohm resistor’ to create gaps for other

traces to pass through. Double-sided and

multi-layer PCBs give the board designer

more routing options than a single-sided

design. This reduces the need for wire links

and unnecessary components. Multi-layer

boards can also offer superior performance,

particularly in high frequency circuits where

having separate layers for ground, power and

signals can reduce noise. Double sided and

multi-layer boards allow wider circuit traces

for a given board area. This reduces resistance

and inductance. The ability to designate areas

of copper as a heatsink can also improve

component reliability.

Last month, we looked at several different

methods for producing single-sided (SS)

PCBs. The same techniques can also be

applied to the production of double-sided (DS)

boards. In most cases, DS boards are made

using double-sided PCB laminate, although

I have also made boards from a pair of thin

SS laminates that were etched separately and

then bonded together using epoxy adhesive.

The resulting board was the same thickness

as standard 1.6mm PCB.

For home produced DS boards, the most

common approach is to use a DS PCB

laminate. It is possible to apply the resist

and etch both sides of the board at the same

time. I find it much easier to do each side as a

separate process. Etch resist is applied to one

side of the board using any of the methods

described last month. The other side is

masked from the etchant using a coat of paint

or a few overlapping strips of plastic tape. The

board is then etched in the normal way. After

etching and cleaning the board, the mask is

removed from the other side. Etch resist is

applied to the second side, a new mask is

applied to the previously etched side and the

board is placed in the etchant for a second

time. For most designs, accurate alignment

of the two sides is critically important. Most

PCB CAD layouts show the board outline and

special alignment marks for this purpose.

In the distant past, I used aerosol car paint

or clear lacquer as the etchant mask. This

makes an excellent mask as it is absolutely

waterproof. Drying time for the two sides

adds at least an hour to the full process. After

etching, the mask could be removed using

paint stripper. I find this is getting progressively

more difficult as the new formulas for paint

stripper seem quite ineffective. I now use

overlapping strips of PVC insulating tape,

as shown in

Photo 1

. This is very effective

provided you drive out air bubbles and make

sure there are no gaps where the etchant

can reach the copper foil. This method is

much quicker than painting because there is

no drying time and the mask is very easily

removed.

RF amplifier/attenuator

One type of double-sided board that is very

effective for HF to UHF circuits uses one

complete side of the board as a continuous

ground plane. Ground connections are made

by soldering the component leads directly to

the top foil. The area around holes for non-

grounded component leads is cleared of

copper. This is achieved by etching or, more

commonly at home, by countersinking the

hole using a larger drill bit as a hand tool.

Signal and power traces are on the opposite

side of the PCB. As a simple project, we will

make a HF amplifier using this technique. As

I often have need for a 50Ω adjustable gain

block, this two stage amplifier will be used

in combination with a pair of 50Ω switched

attenuators to make a useful bench amplifier

with gain/loss adjustable in 10dB steps

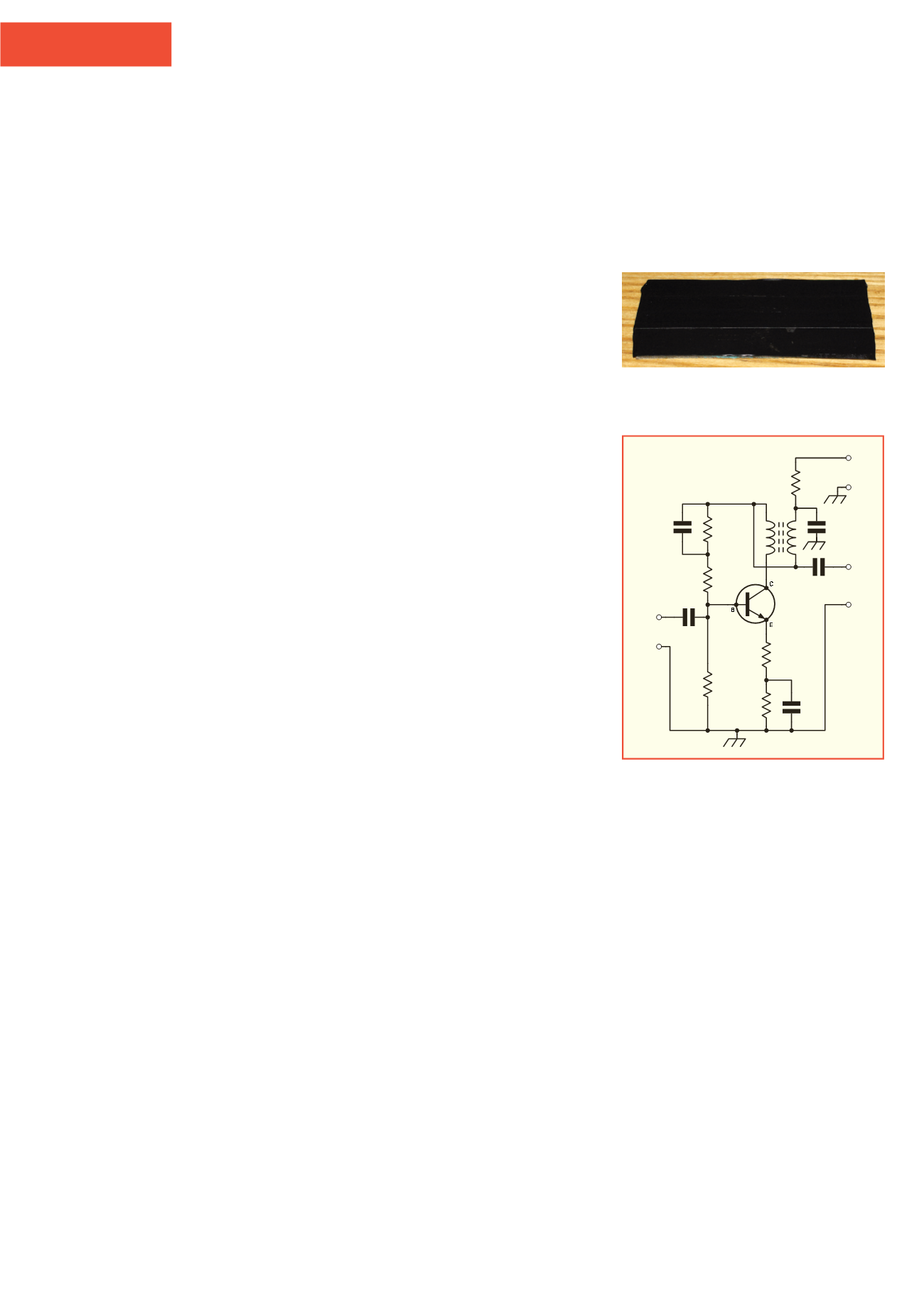

from -30dB to +40dB. The schematic for

each amplifier stage is shown in

Figure 1

.

Component values are chosen for a stage gain

of 20dB.

The resist was applied by hand using a

standard etch-resist pen. I used a printout of

a PCB CAD layout as a reference. The holes

were drilled before applying the etch-resist so

that they could be used as a guide for drawing

the tracks. After drilling, the copper was

cleaned and flattened using wet or dry paper.

This is important because an uneven surface

could allow etchant to enter the masked side

via the drill holes. The resist was left to dry

for one hour before masking and etching. I

used a few strips of PVC insulating tape as a

mask for the top side.

The board was etched using a ferric

chloride solution and washed off with clean

water. The track side (bottom) is shown in

Photo 2

: not pretty, but perfectly functional.

Note that there is no copper around some

of the holes. These are for leads that are

soldered to the ground foil on the other side.

The holes were drilled with a 0.9mm drill

and I used a new and sharp 5mm HSS bit

as a hand tool to remove copper from around

each non-ground connection on the top of

the board. You only need to make one or

two turns of the drill bit to remove sufficient

copper. Don’t use a power drill for this, as

Homebrew

Technical

MPSH10

4Ω7

100Ω

0 1

1k

510Ω

3k3

0 1

0 1

In

T1

0 1

56Ω

0 1

DC

Out

FIGURE 1:

50Ω amplifier

stage (see text).

PHOTO 1:

Using strips of PVC masking tape as

an etchant mask.